Black Friday, Cyber Monday, Super Saturday—let’s talk numbers. In 2018, 165 million people shopped over Black Friday weekend from Thanksgiving to Cyber Monday. Sales on Black Friday totaled over $24 billion. On Cyber Monday, consumers spent $7.9 billion online, a third of which came from mobile devices. Despite these massive numbers, this year’s forecasts for Super Saturday on December 22nd have it surpassing Black Friday with a total of $26 billion.* Clearly, as online shopping continues to grow, the infamous stampede at store openings continues to evolve.

Forecasting is a critical element of each year’s frenzied holiday shopping season. Predictions attempt to anticipate the behavior of the consumer—what they’re buying, from where, and how—so that retailers can prepare. Alongside the rise of e-commerce is the growth of just-in-time operations: the right materials, to create the right product, to be sent to the right locations at just the right time. The everyday consumer now expects retailers to have what they need in stock, and they don’t want to wait for it. They have also come to expect same-day or two-day shipping as the norm in their e-commerce experience.

What does it take to deliver on these expectations at scale consistently, including during high-volume seasons? Fulfillment centers, where a product is sent from the seller and managed, prior to being shipped, are pivotal to the process. Recent advances in AI are making it possible to forecast demand far more accurately, enabling demand-driven staffing of fulfillment centers and true just-in-time operations year round.

A seller sends a product to the fulfillment center where the provider then ships merchandise directly to either a customer, wholesaler, or retailer. The fulfillment center may be a warehouse that is millions of square feet and sees more than a thousand truckloads weekly. Larger companies have their own fulfillment centers, while others outsource it. Amazon’s fulfillment centers handle warehousing, order processing, picking, packing, and shipping.

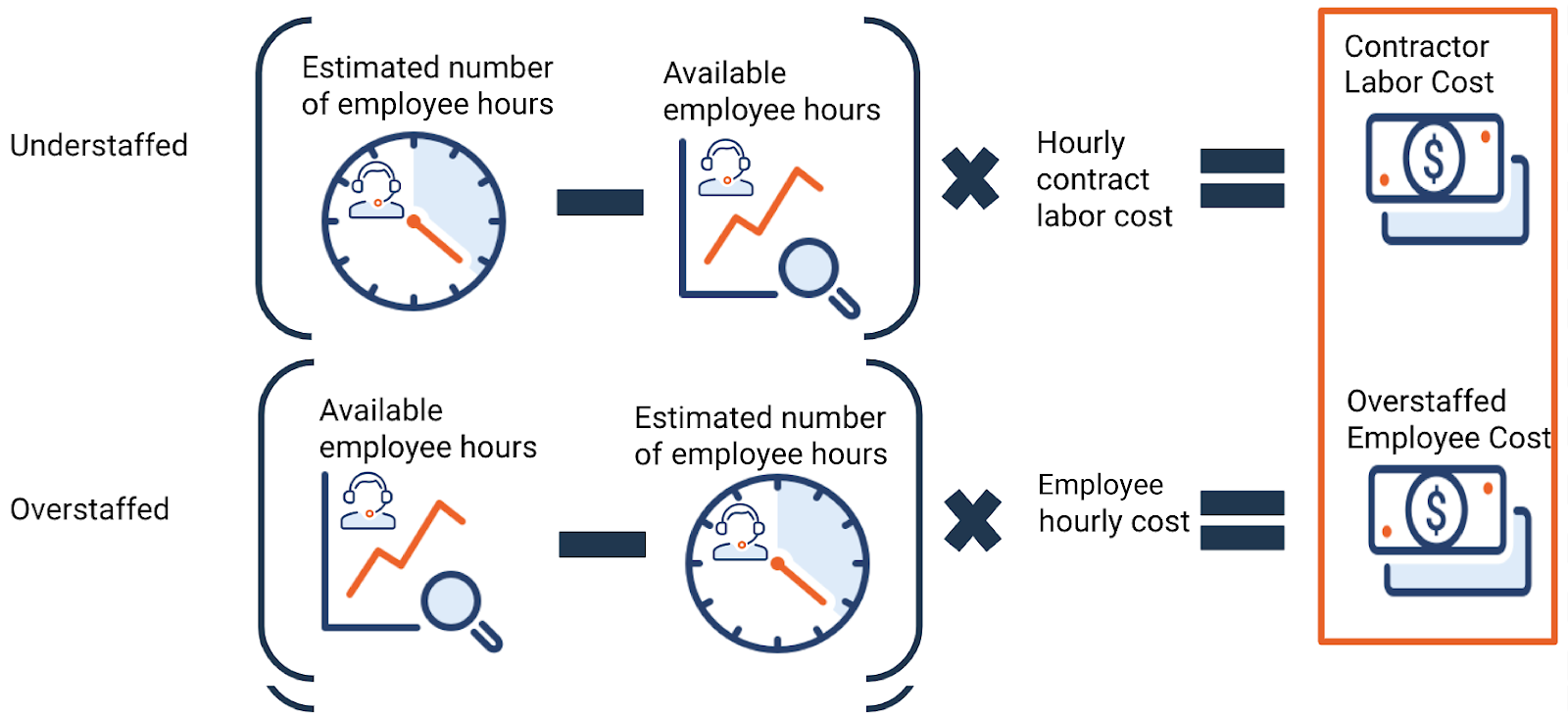

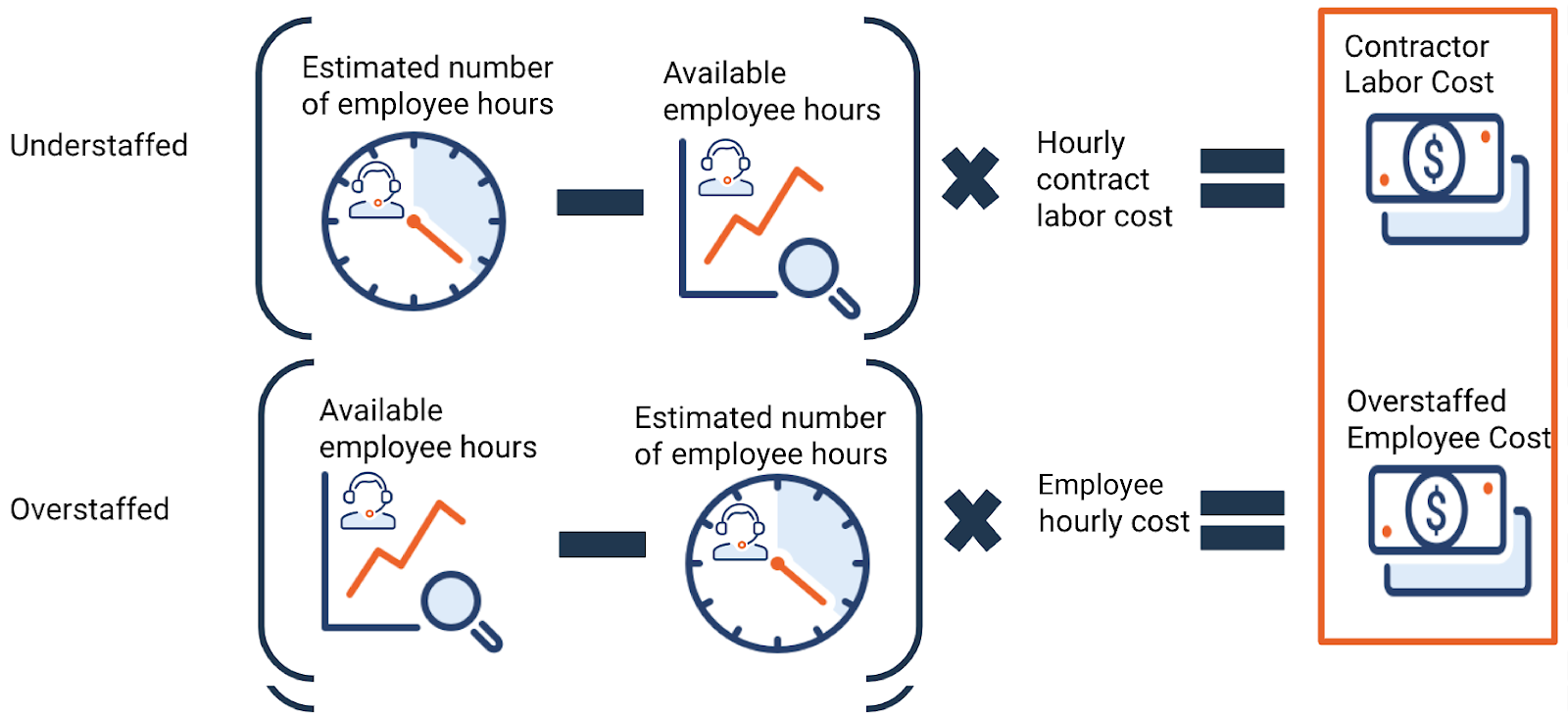

Fulfillment centers have proven essential to scaling operations by separating the problem of inventory management from the sale of merchandise. But, in order to maintain those operating efficiencies, especially during highly fluctuating seasonal and holiday inventory changes, staffing is pivotal to obtaining operational excellence. Fulfillment center staffing impacts revenue in two major ways related to the estimation of demand. An overestimation results in under-utilized employees and unjustified expenses, while underestimation leads to missed delivery windows and the hiring of contractors—who require higher rates but are less efficient—to make up the gap.

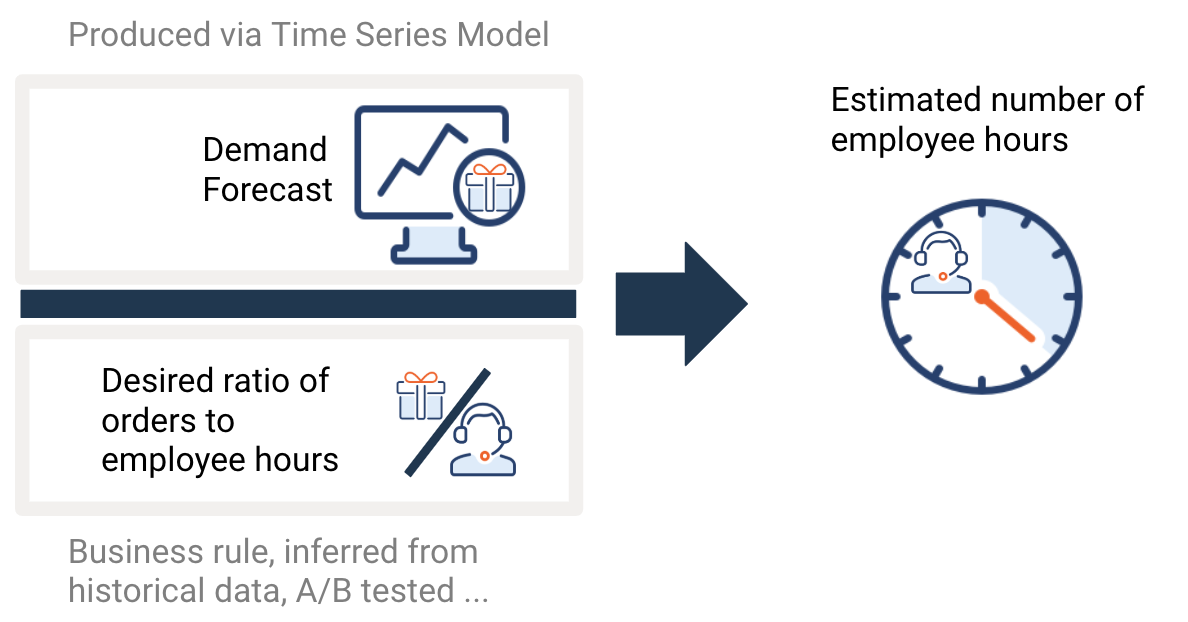

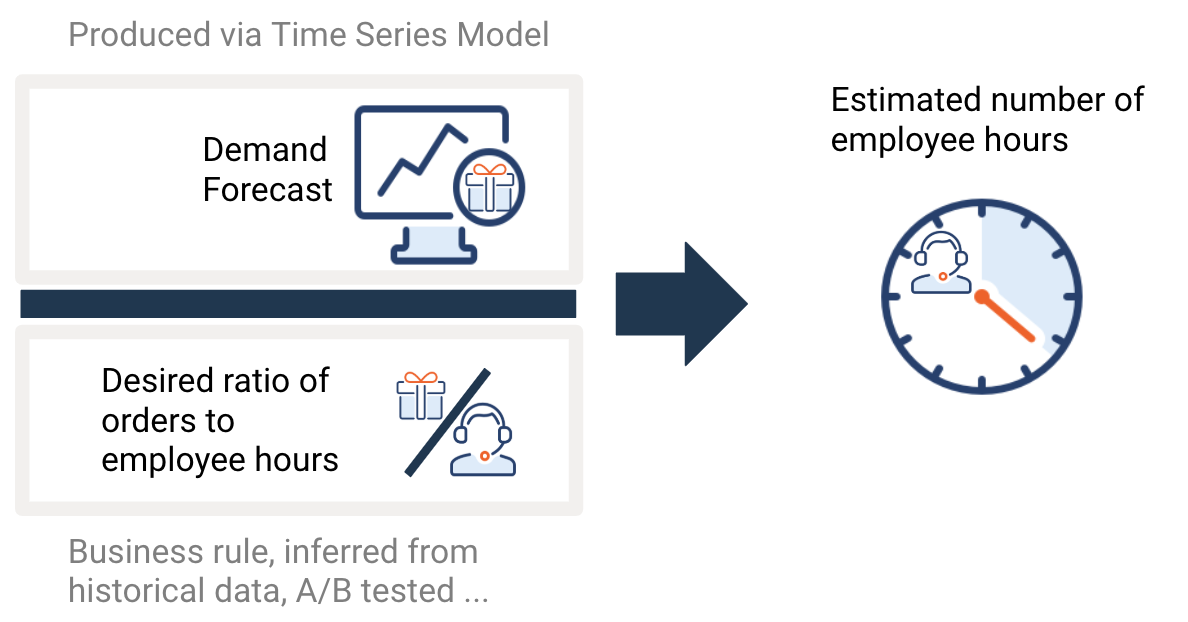

Beyond inventory management software and traditional methods, fulfillment centers can gain a competitive edge operationally by using AI to power demand-driven staffing. Machine learning methods, particularly time series, enables true just-in-time operations through staffing optimization, capacity planning, and shipping. Up until recently, time series forecasting has been seen as a major investment, requiring a lot from your data scientists and your computing resources. What makes manually coding time series forecasts so involved? There are numerous factors.

Intuitively, how would you predict demand for a given day? You could base it off demand yesterday, or the same weekday last week, or the same day last year. You could average the demand of the last week and use that for today—or two weeks back, a month, a year. These kinds of variables, when put into a time series model, are called lags. Different products will require different strategies with lag variables. For example, a consumer may buy bread once a week but will buy baking essentials every few months. Turkey sales will spike before Thanksgiving Day, but eggnog may sell for weeks around Christmas.

This is why time series forecasting has historically been so challenging. You have to derive many lag variables to search for patterns across different lengths of time. Typically, this is an intensive, manual process that exponentially increases the number of variables. To make matters more complicated, time series projects also account for seasonality through the use of calendars. So, a forecast recognizes the days leading up to a given event, such as Thanksgiving, as atypical. Another area where time series gets tricky is with products that have what we’d call discontinuous series. These are products that may only be sold for a season, like Halloween pumpkins, or were either introduced to or removed permanently from production during the time you’re considering. Finally, because time series has so many variables, the only way to ensure the best forecasting performance is to have an iterative process in which a time series project is built and rebuilt with differing strategies.

After all this, you’d hope the resulting time series forecast would be reliable for a long time, but the reality is that demand changes quickly. Time series models need to be monitored and retrained regularly to ensure that they’re accurately capturing the way consumers are behaving today.

This is where the power of automation comes in, greatly reducing the resource investment and traditional time series expertise needed to begin time series forecasting–and driving more accurate forecasting by automating the ability to work iteratively and quickly through multiple scenarios. Within DataRobot, practices like lag feature derivation, the use of calendars, differencing strategies, preprocessing and competitive selection between forecasting models are all automated. Model monitoring and deployment methods are also automated to simplify retraining so that you and your team can keep focused on what the forecast means for your business. DataRobot makes it easy to forecast demand through seasonal changes with high accuracy, ensuring that your customers’ demands are delivered on their terms. This AI-driven demand forecast will increase your operational efficiencies in capacity planning and staff scheduling, as well as time-to-deliver shipment SLAs.

But let’s get back to the numbers. AI is kind of like a tree that falls in the forest. If no one is around to hear it, does it make a sound? If AI-driven time series forecasting models are being created, are they making an impact? In our case, it’s a resounding yes. Last year, a large retailer in Asia used DataRobot to improve their demand forecast accuracy by 9.5%, resulting in an estimated profit of $400 million per year. Another major retailer in the western hemisphere saved an estimated hundreds of thousands a week per fulfillment center.

Not every day is Black Friday. But even at the daily level, using AI-powered demand-driven staffing of fulfillment centers drives greater operational efficiencies for major returns.

About the Author

Sarah Khatry is a data scientist at DataRobot and initially joined the company as part of the Applied Data Science Associate Program. Prior to joining DataRobot, Sarah worked in the film and entertainment industry working on script development and interfacing with screenwriter clients. Sarah has her B.A. in English and Physics from Dartmouth College.

Ebook

Next-Generation Time Series

Forecasting for the Real World, Not the Ideal World

Download Now

About the author

Sarah Khatry

Applied Data Scientist, DataRobot

Sarah is an Applied Data Scientist on the Trusted AI team at DataRobot. Her work focuses on the ethical use of AI, particularly the creation of tools, frameworks, and approaches to support responsible but pragmatic AI stewardship, and the advancement of thought leadership and education on AI ethics.